Our CNC Turning Manufacture

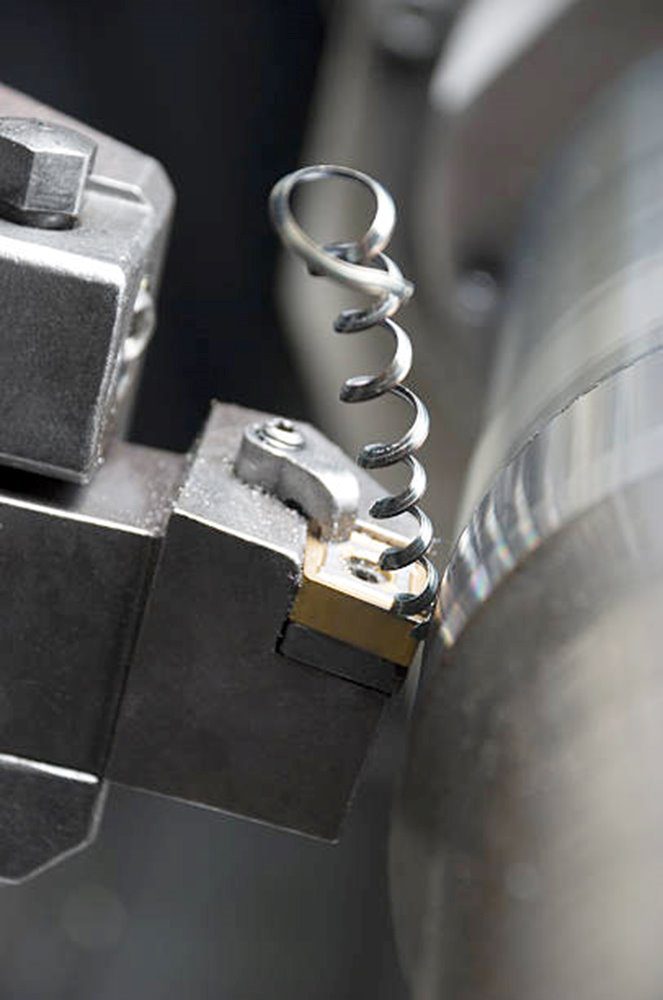

Providing high-precision machining for cylindrical parts and components. With our state-of-the-art CNC lathes, we craft custom turned parts with unparalleled accuracy, ensuring they meet the exact requirements of your design. Whether for prototyping or large-scale production, our expertise guarantees results that exceed industry standards.

CNC Turning Capabilities at Batnon

- Precision and Accuracy: Achieving tight tolerances as fine as ±0.005mm for even the most intricate designs.

- Part Size: Supporting diameters up to 300mm and lengths up to 600mm, accommodating small and medium-sized components.

- Material Flexibility: Expertise in machining metals, plastics, and specialty alloys.

- Complex Features: Manufacturing parts with threads, grooves, tapers, and intricate internal details.

- Production Scalability: From one-off prototypes to high-volume production, Batnon ensures consistent quality for all cnc turned parts.

Advantages of Choosing Batnon for CNC Turning

- Quick Turnaround Times: With our quick turn CNC machining, we deliver parts faster without compromising precision.

- Customization: Tailored solutions for unique designs and specific applications.

- Advanced Technology: Equipped with high-performance CNC lathes for superior results.

- Comprehensive Support: End-to-end services, including design assistance and quality inspection.

- Competitive Pricing: Cost-effective turning services for all project sizes.

Industries Served for CNC Turning

- Aerospace

We craft high-precision cnc turned parts like bushings, connectors, and custom fasteners that meet the strict performance and safety standards of the aerospace industry. Our parts are designed to perform under extreme conditions with tight tolerances.

- Automotive

Our expertise in turning machining produces critical automotive components such as shafts, pistons, and gears. These components ensure high durability and functionality in modern vehicles while meeting strict industry standards.

- Automation

We provide precision turning services for automation systems, including custom cylindrical components and connectors. These parts help enhance the efficiency and reliability of automated manufacturing systems.

- Robotics

Batnon supports the robotics industry with high-precision parts like pins, joints, and custom connectors. Our custom turned parts ensure seamless movement and high performance in robotic assemblies.

- Medical Devices

With expertise in precision machining, we manufacture components for medical devices such as surgical instruments, implants, and precision housings. All parts meet stringent regulatory and safety standards for the healthcare sector.

- Electronics

Our cnc turning services deliver compact and precise parts like connectors, enclosures, and custom fittings for electronics. We specialize in crafting small, intricate components required for high-tech devices.

- Industrial Equipment

We produce durable and high-quality machining parts for industrial machinery, including bushings, shafts, and couplings. These components enhance the reliability and performance of heavy-duty equipment.

- Consumers

Batnon creates custom turned parts for consumer products, combining precision and aesthetic appeal to meet the demands of high-end consumer markets. From home appliances to personalized designs, we deliver on functionality and style.

- Machinery

We support the machinery industry with robust and reliable metal machining solutions, such as rollers, pulleys, and fixtures. Our parts are designed for high performance and extended durability.

- Aircraft

Our high-precision cnc lathe services produce critical aircraft components like spindles, bearings, and mounts. These parts ensure safety, reliability, and performance in demanding flight conditions.

Materials for CNC Turning

Metals:

Aluminum (6061, 7075, etc.) – Lightweight, corrosion-resistant, and versatile.

Stainless Steel (304, 316, 410, etc.) – Durable, strong, and corrosion-resistant.

Tool Steel – Ideal for high-strength tools, molds, and dies.

Spring Steel – Excellent elasticity and fatigue resistance.

Carbon Steel – High strength and excellent machinability.

Titanium – High strength-to-weight ratio, ideal for aerospace and medical.

Brass – Good electrical conductivity and corrosion resistance.

Copper – Excellent thermal and electrical conductivity.

Magnesium – Extremely lightweight and high machinability for automotive and aerospace applications.

Tungsten – Extremely dense, hard, and heat-resistant for specialized applications.

Invar – Exceptional dimensional stability with minimal thermal expansion, ideal for precision instruments and aerospace applications.

Kovar – Excellent thermal expansion compatibility with glass and ceramics, perfect for hermetic seals in electronic and optical components.

Plastics:

Acrylic

Delrin

Garolite G-10

HDPE

РЕЕК

Polycarbonate

Polypropylene

PPS

PTFE

PVC

Torlon UHMW

Ultem

Other Specialty Materials:

NBR Nitrile, silicone, rubber, Engineering Plastics.

Material Recommendations:

Aerospace & Medical: Use Titanium, Stainless Steel, or PEEK for strength and precision.

Automotive & Industrial: Aluminum, Carbon Steel for balance of cost and performance.

Electronics: Copper and Brass for electrical conductivity.

Prototyping: ABS, Nylon, or Aluminum for cost-efficiency and fast production.

Tolerances

- Achievable Tolerance: ±0.005mm, ensuring superior fit and performance for every part.

- Ideal for industries requiring precision-engineered custom turned parts.

Tolerances Matter

- In industries like aerospace, medical devices, and automotive, even minor deviations in tolerances can lead to functional failures or poor part fit. At Batnon, we ensure every part meets exact specifications through our advanced multi-axis CNC machining technology.

Surface Finishes

- As-Machined: Smooth, standard finish directly from the CNC process.

- Polished: Reflective, glossy surface.

- Anodizing: Enhances corrosion resistance and aesthetics (available in multiple colors).

- Powder Coating: Durable finish for wear resistance.

- Sandblasting: Uniform matte surface.

- Plating: Nickel, zinc, or chrome plating for functional or decorative purposes

- Galvanizing:Zinc coating applied to steel or iron parts for enhanced corrosion resistance and durability, ideal for outdoor or industrial applications.

- Electrophoresis: A uniform, electrically-applied coating that enhances corrosion resistance and provides a smooth, durable surface finish, suitable for decorative or functional purposes.

- Tumbling: A finishing process that smooths and polishes parts by gently rotating them with abrasive media, ideal for removing sharp edges and achieving a uniform matte or polished finish.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Need a specific material or precision tolerance?

Our experts will tailor solutions to meet your requirements

Applications of CNC Turning

FAQs

1. What types of components can CNC turning create for specific industries?

Our cnc turning service can produce a variety of cylindrical components, including shafts, bushings, threaded parts, and couplings, tailored to meet the requirements of industries such as aerospace, medical, and automation.

2. Can CNC turning handle complex custom designs?

Absolutely. Batnon specializes in crafting custom turned parts with intricate features, including threads, grooves, and tapers, ensuring precision and functionality for even the most demanding applications.

3. How quickly can you deliver CNC turned components for urgent projects?

Using quick turn CNC machining, we can deliver prototypes or small production batches in as little as 7–10 days, depending on the complexity and material requirements.

4. Are there limitations on the size of parts produced with CNC turning?

Our cnc lathe services accommodate parts up to 300mm in diameter and 600mm in length, making us well-equipped to handle a range of small to medium-sized components.

5. Is CNC turning suitable for high-precision applications?

Yes, our turning machining processes achieve tolerances as tight as ±0.005mm, making them ideal for applications requiring extreme precision, such as in medical devices or robotics.

6. Can Batnon produce both prototypes and high-volume turned parts?

Yes, we offer scalable turning services to support both prototyping and mass production, ensuring consistent quality across all orders.

7. What materials can you use for CNC turning applications?

We work with a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics, to provide versatile cnc turned parts for various industries.

Ready to elevate your project

with our precision CNC machining services?