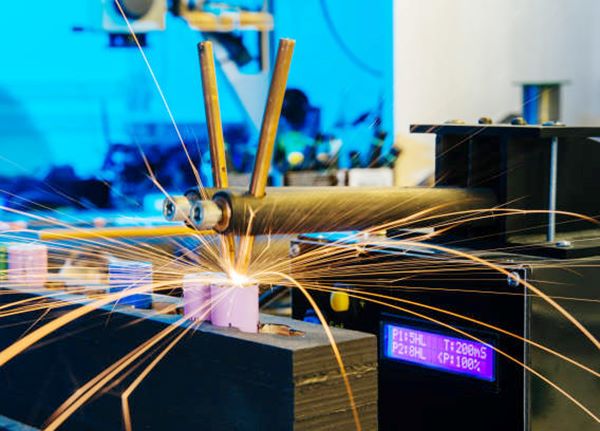

Our Welding Services

At Batnon, we provide a comprehensive range of welding services to deliver precision-engineered products tailored to your specifications. From laser beam welding for intricate assemblies to spot welding for high-strength joints, our team ensures unparalleled quality and efficiency. Our certified welders combine expertise with state-of-the-art technology to meet the diverse needs of industries worldwide.

Overview on Welding

Welding is a critical process in sheet metal fabrication, often combined with other techniques to create finished, durable, and reliable products. At Batnon, we specialize in versatile types of welding, including MIG, TIG, spot, and robotic welding, ensuring precision and consistency across all projects. Whether it’s a small component or a large-scale structure, our expertise guarantees seamless integration with your manufacturing requirements.

Our Welding Capabilities

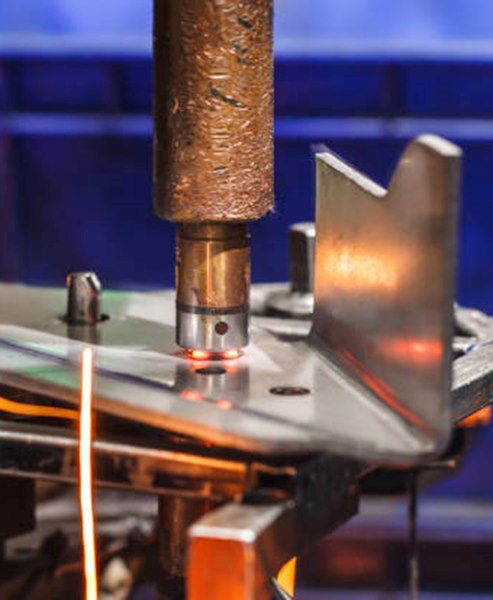

Processes: TIG, MIG, spot welding, robotic welding, and laser beam welding.

Materials: Expertise in aluminum welding, stainless steel, mild steel, and exotic alloys.

Equipment: Advanced robotic arms, aluminum welders, and precision spot welders.

Production Scale: From prototypes to large-volume production runs.

Certifications: All welders are certified to meet international standards, ensuring reliable and high-quality welds.

Advantages of Choosing Batnon for Welding

Custom Solutions: Tailored welding services to match your exact specifications.

Certified Welders: Professionals with extensive experience in complex projects.

Efficiency: Fast turnaround times without compromising quality.

Cutting-edge Technology: Incorporating the latest in laser beam welding and robotic welding techniques.

End-to-end Support: From design consultation to post-production finishing.

Industries Served

Our welding expertise spans a diverse range of industries:

Automobile

Automation

Medical

Energy

Robotics

Electrical

Aerospace

Consumers

Food and Beverage

Electronics

Printing

Machinery and Equipment

Aircraft

Materials

We specialize in welding the following materials:

Aluminum

Stainless steel

Carbon steel

Titanium

Nickel alloys

Brass and copper

Inconel and other superalloys

Material Recommendations

Aluminum Welding: Ideal for lightweight and corrosion-resistant applications such as aerospace and automotive components. Stainless Steel Welding: Perfect for industries requiring strength, durability, and hygiene, such as food and medical equipment. Carbon Steel Welding: Best suited for structural applications demanding high tensile strength.

Tolerances

Our welding services achieve precise tolerances to meet industry standards, ensuring:

Dimensional accuracy

Consistent joint strength

Seamless fit and finish Typical tolerances range from ±0.005 inches, depending on material and project complexity.

Tolerances Matter

“In industries like aerospace, medical devices, and automotive, even minor deviations in tolerances can lead to functional failures or poor part fit. At Batnon, we ensure every part meets exact specifications through our advanced multi-axis CNC machining technology.”

Surface Finishes

- As-Machined: Smooth, standard finish directly from the CNC process.

- Polished: Reflective, glossy surface.

- Anodizing: Enhances corrosion resistance and aesthetics (available in multiple colors).

- Powder Coating: Durable finish for wear resistance.

- Sandblasting: Uniform matte surface.

- Plating: Nickel, zinc, or chrome plating for functional or decorative purposes

- Galvanizing:Zinc coating applied to steel or iron parts for enhanced corrosion resistance and durability, ideal for outdoor or industrial applications.

- Electrophoresis: A uniform, electrically-applied coating that enhances corrosion resistance and provides a smooth, durable surface finish, suitable for decorative or functional purposes.

- Tumbling: A finishing process that smooths and polishes parts by gently rotating them with abrasive media, ideal for removing sharp edges and achieving a uniform matte or polished finish.

Have a challenging welding project? Our certified welders and engineers are here to help. Contact us for expert advice and tailored solutions to bring your vision to life.

Quality Control

Quality is at the core of everything we do. Our rigorous quality assurance process includes:

Visual and dimensional inspections

Non-destructive testing (NDT)

Tensile strength and fatigue testing

Documentation to meet industry standards

FAQs

Q1: What types of welding do you offer?

A: We specialize in MIG, TIG, spot welding, robotic welding, and laser beam welding.

Q2: Can you weld aluminum?

A: Yes, our certified welders excel in aluminum welding for industries such as aerospace and automotive.

Q3: What is the maximum size of components you can handle?

A: We can weld components up to 10 feet in length and 5 tons in weight.

Q4: Do you provide surface finishing?

A: Yes, we offer a range of surface treatments, including polishing, anodizing, and powder coating.

Q5: How can I get a quote for welding services?

A: Contact us at sales@batnon.com or use our online quote request form for a quick response.

Fast Quote Within 12 Hours!

For inquiry or questions, please send your message, we’ll respond soon!