Main content: Processing Procedure of Aluminum Extrusion Profile.

The processing process of aluminum profile includes the following three steps: melting & refine, extrusion and coloring (the key of coloring includes oxidation, electrophoresis process, fluorocarbon painting, electrostatic powder spraying, wood grain transfer, etc.). This article is about these three steps.

1. Melting and Refining

Melting is the process of dissolving aluminum ingots into aluminum rods. Smelting is divided into three steps:

(1) Seasoning: calculate the addition amount of various aluminum alloy ingredients according to the actual aluminum alloy model that must be produced and manufactured, so as to effectively match various raw materials.

(2) Smelting: put the selected raw materials into the smelting furnace for melting according to the processing regulations, and reasonably remove the miscellaneous slag and steam in the solution according to the degassing and slag discharge refining methods.

(3) Forging: the liquid aluminum in the smelting furnace is cooled and cast into round rods of various specifications.

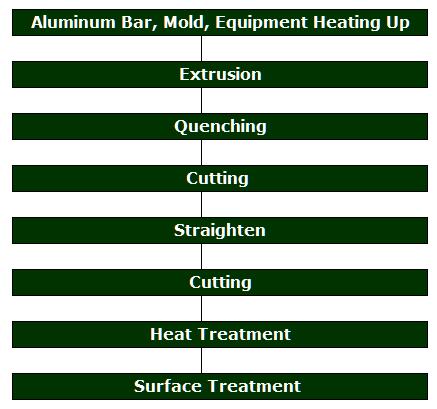

2. Extrusion

In extrusion production, the heated round cast rod is extruded from the die by extruder. The common model 6063 aluminum alloy also uses an air-cooled heat processor for the whole process heat treatment during extrusion. The heat treatment process of different models of aluminum is also different.

3. Coloring

In the coloring process of aluminum profile, anodizing is the most widely used, it’s one of the important steps in aluminum profile processing. When aluminum profile is made, its surface corrosion resistance is not strong yet, anodizing can improve the corrosion resistance, wear resistance and surface appearance.

The anodizing process is as following:

(1) Preparation: clean the profile surface by means of organic chemistry or physics, which is conducive to the formation of a dense and high-density oxide film on the profile surface. Supplemented by other processing methods, the surface of aluminum profile can also be made into mirror effect or mirror / matte effect.

(2) Anodizing: the surface pretreated profile will undergo anodizing reaction in the oxidation tank, and a layer of Al203 oxidation film with high density, porous structure and strong adsorption will be formed on its surface.

(3) Grouting reinforcement: the function of this step is to close the pores of the porous structure (i.e. the membrane pores of the oxide film) formed during anodic oxidation, so as to improve the pollution resistance, corrosion resistance and wear resistance of the oxide film. The oxide film is colorless and completely transparent. With the help of the strong adsorption force of the oxide film before grouting reinforcement, if the membrane hole can absorb some metal salt components, the profile surface can show many different colors other than the primary color (silver), such as gray black, copper, orange and stainless steel. This is why we can see different colors by oxidizing.

Process flow of aluminum profile processing.

( Like this article, click the share button)