Our Extrusion Profile Services

At Batnon, we specialize in creating high-quality extruded aluminum profiles and custom shapes tailored to meet the unique needs of our clients. From lightweight aluminum channels to intricate T-slot aluminum extrusions, our advanced manufacturing techniques deliver exceptional results for industries worldwide.

Overview on Aluminum Extrusion Profile

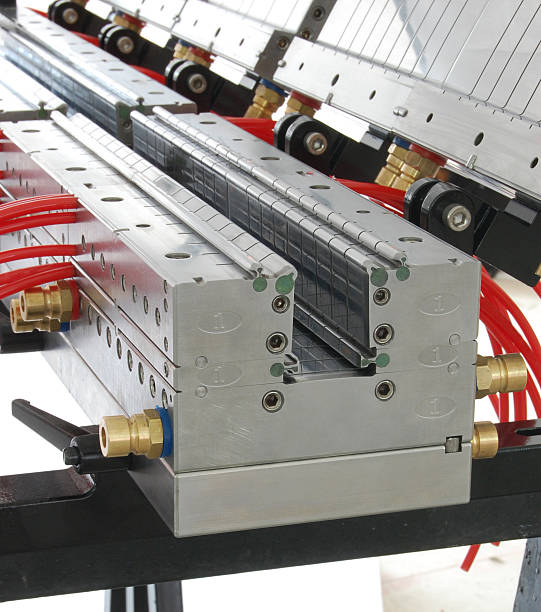

Extrusion is a manufacturing process that shapes materials by forcing them through a die. At Batnon, we utilize advanced profile aluminum extrusion technology to produce highly accurate, durable, and customizable profiles for a wide range of applications. Our expertise extends to both aluminum extrusions profiles and custom plastic extrusions, ensuring versatility and innovation in every project.

Our Aluminum Profle Capabilities

Key Features of Our Extrusion Profile Services

- Custom Design: We create tailored designs, from intricate T-slot extruded aluminium to functional aluminum channel extrusions.

- Part Size: Capable of producing profiles up to 12 meters in length.

- Material Options: Expertise in aluminum profile extrusion and plastic extrusions for diverse applications.

- Production Scalability: Supporting prototypes, small batches, and high-volume production with consistent quality.

Advantages of Choosing Batnon for Aluminum Extrusions

- Design Flexibility: Ability to create complex shapes and custom designs.

- Lightweight and Durable: Perfect for applications requiring strength without added weight.

- Cost-Effective: Efficient extrusion profile processes minimize material waste.

- Consistent Quality: Advanced technology ensures uniformity across all profiles.

- Material Versatility: Options for extruded aluminum profiles and plastic extrusions to meet specific requirements.

Applications of CNC Milling

Our extrusion profile services excel in producing components for:

- Structural Frameworks: Lightweight and durable solutions for automation systems and robotics.

- Architectural Elements: Custom aluminum profiles for decorative and functional use.

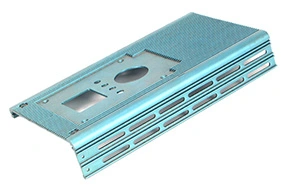

- Electronics Enclosures: Sleek and durable extruded profiles for electronic devices.

- Transport Components: High-strength parts for automotive, aerospace, and railway applications.

- Industrial Equipment: Custom-fit profiles for machinery and processing equipment.

Industries Served

Batnon’s extrusion profile manufacture services cater to a wide array of industries, including:

- Automobile: Lightweight aluminum extrusions profiles for vehicle frameworks and decorative trims.

- Automation: Custom T-slot aluminum extrusions for modular systems and structural supports.

- Medical: Durable and precise profiles for medical devices and equipment housings.

- Energy: Corrosion-resistant profiles for renewable energy systems and infrastructure.

- Robotics: Structural components for robotic arms and automation setups.

- Electrical: Compact and efficient extruded aluminum profiles for enclosures and connectors.

- Aerospace: Lightweight and durable components for high-performance aviation systems.

- Consumers: Sleek and functional profiles for furniture, appliances, and design products.

- Food and Beverage: Hygienic and corrosion-resistant profiles for food processing equipment.

- Electronics: Custom extrusions for heat sinks, enclosures, and connectors.

- Printing: Precision profiles for high-performance printing machinery.

- Machinery and Equipment: Durable extrusions for structural integrity and efficiency.

- Aircraft: High-strength profiles for aviation applications, combining lightness and durability.

Materials

Materials We Work With

- Aluminum: Strong, lightweight, and corrosion-resistant, ideal for most applications.

- Plastic: Flexible and durable, perfect for non-metal applications requiring versatility.

- Specialty Alloys: For applications requiring enhanced strength or unique properties.

Material Recommendations

- Aluminum: The most popular choice for extruded aluminum profiles, offering excellent strength-to-weight ratio and corrosion resistance.

- Plastic: Ideal for lightweight and cost-effective solutions in consumer and medical applications.

- Specialty Alloys: Recommended for aerospace and automotive applications where performance is critical.

Tolerances

Our extrusion profile processes ensure precision and accuracy:

- Standard Tolerances: ±0.5mm for general applications.

- High-Precision Tolerances: ±0.1mm for intricate designs and critical components.

Tolerances Matter

“In industries like aerospace, medical devices, and automotive, even minor deviations in tolerances can lead to functional failures or poor part fit. At Batnon, we ensure every part meets exact specifications through our advanced multi-axis CNC machining technology.”

Surface Finishes

Enhance the performance and appearance of your extrusion profiles with professional surface treatments:

- Anodizing: Provides a durable, corrosion-resistant finish in a variety of colors.

- Powder Coating: Adds a protective and decorative layer for enhanced durability.

- Polishing: Achieves a smooth and reflective finish for decorative applications.

- Brushing: Adds texture for aesthetic appeal while maintaining functionality.

Navigating the complexities of custom aluminum extrusions and plastic extrusions can be challenging. At Batnon, our team of experts is here to guide you through every step, from design to material selection and production optimization.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Certifications:

- ISO-compliant processes for guaranteed reliability.

Case Study

Project Requirement:

An automation company required custom T-slot aluminum extrusions for modular frameworks. The profiles needed to be lightweight yet durable, with precise tolerances for seamless assembly.

Our Solution:

- Designed and manufactured tailored extrusion profiles to match the client’s specifications.

- Delivered 1,000 units with consistent quality and an anodized finish for corrosion resistance.

Results:

The client successfully deployed the extrusions, enhancing the system’s modularity and reducing assembly time.

Client Feedback:

The client praised the part’s exceptional quality and early delivery, enabling them to successfully integrate it into their robotics system and launch on time.

Impact:

This project reinforced Batnon’s reputation as a trusted CNC milling partner for high-precision, time-sensitive projects, particularly in the robotics and automation industries.

FAQs

1. What is the maximum length for extrusion profiles you can produce?

We can produce profiles up to 12 meters in length, depending on material and application needs.

2. Can you create custom designs for extrusion profiles?

Yes, we specialize in custom aluminum extrusions and plastic extrusions, ensuring tailored solutions for unique requirements.

3. What industries use your extrusion profile services?

We serve industries including automotive, aerospace, medical devices, industrial equipment, and more.

4. What materials are best for extrusion profiles?

Aluminum is the most versatile and popular choice, but we also work with plastics and specialty alloys for specific needs.

5. What surface treatments are available?

We offer anodizing, powder coating, polishing, and brushing to enhance functionality and aesthetics.

6. How precise are your extrusion profiles?

We achieve tolerances as tight as ±0.1mm, ensuring accuracy for even the most critical applications.

Ready to elevate your project

with our precision CNC machining services?