IMD (In Mold Decoration)

IMD at Batnon

In-Mold Decoration (IMD) is an advanced plastic injection technique that requires higher precision and delivers superior appearance. With over 15 years of experience in IMD production, our strong engineering capabilities and comprehensive machinery enable us to handle large-scale orders efficiently.

1. What is IMD?

IMD (In Mold Decoration) is an injection molding technology in which a film is placed in the injection mold. When the plastic part is thermoformed in the mold, the film will be integrated into the plastic part and become the surface of the plastic part, so as to change the appearance of the plastic surface.

IMD breaks the limitation that the traditional injection molding technology can only produce simple patterns and single colors, and realizes the special needs of obtaining the surface patterns, textures, colors, three-dimensional effects of plastic parts according to any design, creating more exquisite, personalized and high-quality plastic parts. At the same time, the cost and time of surface post-processing of plastic parts are eliminated. In any way, IMD can provide higher standards, more stable quality and lower cost than traditional injection molding.

For traditional surface treatment directly on the surface of plastic parts, there are printing, painting or electroplating processes. These processes are often more expensive, time-consuming, unstable quality and poor effect. What’s more, for plastic parts with curved surface modeling, the traditional surface treatment process can not be realized. On the contrary, IMD is a prepared printed film, which can be printed in any color or pattern according to design needs. These printed patterns will be directly molded on the surface of plastic parts to form a delicate and delicate surface effect.

There’re two ways for making IMD part, one is in mold heat transfer injection molding. This is to stick the film on the front mold. When the plastic parts are injection molded, this film will have a heat transfer effect with the high temperature effect of the plastic parts in the mold. This method is similar to the traditional heat transfer printing. However, this action was completed in the mold, and the plastic parts were not taken out.

The second method is to cut the film into a single piece after it is printed. During each injection interval, the film is put into the mold when the front and rear molds are separated. After the front and rear molds are closed, the film is molded and integrated with the plastic parts in the mold cavity. Obviously, the printed layer made in this way is located below the film, so it can be protected by the outer layer of the film, so it can be well protected without being worn or scratched.

2. Production Procedures of IMD

The In-Mold Decoration (IMD) process flow includes the following steps:

Step 1: Film cutting

Cut the film according to the size required by the design and use it for subsequent printing.

Step 2: Film printing

Various designed patterns and characters are printed on the film.

Step 3: Film drying

Dry the ink on the film to ensure it adheres firmly to the film’s surface.

Step 4: Film protective foil

Applying a protective film prevents wear and damage during handling and placement into the mold cavity.

Step 5: Film locating hole

Place the film into the forming copper mold for heating and shaping to match the plastic part’s design.

Step 6: Injeciton forming

Place the film into the forming copper mold for heating and shaping to match the plastic part’s design.

Step 7: Film trimming

Trim the excess edges and corners of the film to ensure it fits perfectly on the plastic parts.

Step 8: Plastic injection molding

During plastic injection molding, the high temperature in the mold cavity softens the film, allowing it to adhere seamlessly to the plastic part’s surface. This is a crucial step in the IMD process, resulting in the finished IMD workpiece.

The above is the whole process of IMD.

3. What Are The Advantages Of IMD?

Compared with other injection molding, IMD has the bellow advantages:

1) Customization: IMD allows for printing any desired color, pattern, or texture on the film, limited only by the capabilities of the printing equipment and materials. This flexibility means that with the right equipment and materials, we can achieve unique and high-quality IMD effects that surpass traditional surface treatments in terms of color expression.

2) Versatility: Multiple patterns can be produced within the same batch. If there are many patterns in a large batch, the IMD process is ideal, as it does not require a minimum order quantity for a single pattern.

3) Durability: The IMD printing layer is protected beneath a transparent film, shielding it from external wear and tear. This means the printed patterns are resistant to abrasion and paint peeling, common issues with conventional surface treatments.

4. Considerations for IMD Production

1) Batch Size: IMD production requires a minimum batch size to amortize the cost per unit effectively.

2) Expertise: Engineers and operators must have extensive experience. They need to understand the production process and machine characteristics thoroughly, anticipate potential issues, and implement preventive measures.

3) Preparation: More extensive preliminary work and preparation are needed for film preparation.

5. Material Requirements For Film

1) Film thickness: 0.1 mm, 0.125 mm, 0.175 mm

2) Thickness of plastic parts: plastic part wall thickness should be at least 1.0mm, and when film is added, it will be 1.2mm

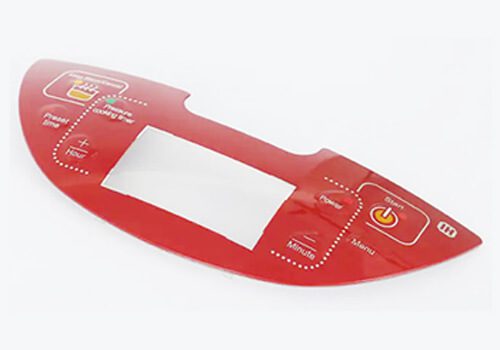

6. Application of IMD

Plastic parts produced using the IMD process are ideal for decorative or indicative components and shells. This includes applications in household appliances, electronic products, medical devices, aviation parts, automobile parts, and more.

IMD Parts Gallay

Manufacture Services:

Fast Quote Within 12 Hours!

For inquiry or questions, please send your message, we’ll respond soon!