Our Metal Bending Services

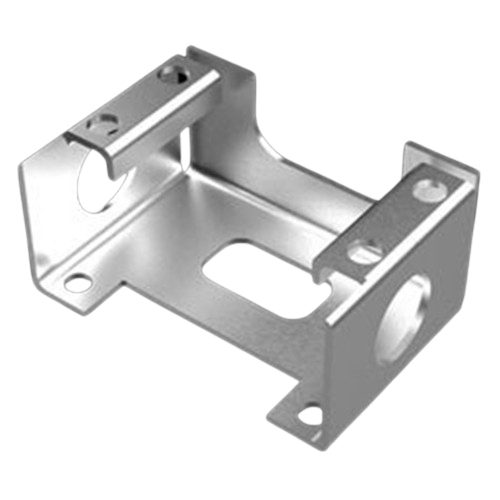

At Batnon, we specialize in custom metal bending to create high-precision components tailored to your specifications. From simple bends to intricate, multi-angle designs, our advanced bend fabrication processes deliver reliable and repeatable results for a wide range of industries.

Overview on Bending Fabrication

Metal bending is a fabrication process where force is applied to deform a sheet or tube into a desired angle or shape. Using state-of-the-art equipment, Batnon ensures consistent, precise, and cost-effective custom sheet metal bending for components of all complexities.

Our Bending Capabilities

Key Features of Our Metal Bending Services

- Bending Precision: Achieving angles as accurate as ±0.5° for precise component fit.

- Material Thickness: Capable of bending metals ranging from 0.5mm to 10mm thick.

- Part Size Range: Accommodating sheets up to 3 meters wide for large-scale projects.

- Custom Solutions: Tailored tooling for custom bent sheet metal and tube fabrication requirements.

Advantages of Bending Fabrication at Batnon

Why Choose Batnon for Metal Bending?

- Flexibility in Design: Our expertise in bending metal allows us to handle complex geometries and multi-radius bends.

- Cost-Efficiency: Minimizes material waste while ensuring consistent quality.

- Advanced Equipment: Equipped with precision press brakes and rollers for enhanced capabilities.

- Scalability: Suitable for prototypes, small batches, and high-volume production runs.

- Customization: Perfect for custom tube fabrication and bespoke sheet metal solutions.

Applications of Metal Bending Fabrication

Our metal bending services excel in producing components such as:

- Automotive: Brackets, panels, and chassis components.

- Industrial Equipment: Frames, housings, and custom structures.

- Architectural Elements: Decorative panels and structural supports.

- Consumer Products: Custom bent parts for furniture, appliances, and hardware.

Industries Served

Batnon’s metal bending fabrication services cater to a diverse range of industries:

- Automobile: Complex bent components for vehicles, including frames and brackets.

- Automation: Custom bent parts for automated systems.

- Medical: Precision-formed housings and brackets for medical devices.

- Energy: Corrosion-resistant components for renewable and traditional energy systems.

- Robotics: Custom tube bending fabrication for robotic arms and frames.

- Electrical: Bent metal enclosures and busbars for electrical systems.

- Aerospace: Lightweight yet durable components for aerospace applications.

- Consumers: Decorative and functional parts for consumer goods.

- Food and Beverage: Corrosion-resistant frames and supports for processing equipment.

- Electronics: Compact, custom-shaped parts for electronic devices.

- Printing: Structural components for printing machines.

- Machinery and Equipment: Bent components for structural and functional purposes.

- Aircraft: Precision-formed brackets and supports for aviation systems.

Materials

Materials We Work With

- Steel: Carbon and stainless steel for durability and strength.

- Aluminum: Lightweight and corrosion-resistant for aerospace and automotive applications.

- Brass: Decorative and functional parts with excellent machinability.

- Copper: High conductivity, ideal for electrical applications.

- Specialty Alloys: For applications requiring enhanced properties.

Material Recommendations

- Stainless Steel: Best for corrosion resistance in medical and food-grade applications.

- Aluminum: Lightweight and versatile for custom designs in automotive and aerospace.

- Brass: Ideal for decorative components requiring a polished finish.

- Copper: Perfect for electrical and thermal applications, such as busbars.

Tolerances

Our metal bending services ensure exceptional accuracy:

- Standard Tolerances: ±0.5° for general applications.

- High-Precision Tolerances: ±0.25° for critical bends in custom components.

Tolerances Matter

Tight tolerances ensure every part fits seamlessly into its intended application, reducing assembly time and costs.

Surface Finishes

- As-Machined: Smooth, standard finish directly from the CNC process.

- Polished: Reflective, glossy surface.

- Anodizing: Enhances corrosion resistance and aesthetics (available in multiple colors).

- Powder Coating: Durable finish for wear resistance.

- Sandblasting: Uniform matte surface.

- Plating: Nickel, zinc, or chrome plating for functional or decorative purposes

- Galvanizing:Zinc coating applied to steel or iron parts for enhanced corrosion resistance and durability, ideal for outdoor or industrial applications.

- Electrophoresis: A uniform, electrically-applied coating that enhances corrosion resistance and provides a smooth, durable surface finish, suitable for decorative or functional purposes.

- Tumbling: A finishing process that smooths and polishes parts by gently rotating them with abrasive media, ideal for removing sharp edges and achieving a uniform matte or polished finish.

Navigating the complexities of custom metal bending can be challenging. At Batnon, our experts provide guidance on material selection, tooling, and design optimization to ensure your project’s success.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Certifications:

- ISO-compliant processes for guaranteed reliability.

Case Study

Project Requirement:

A client needed lightweight, custom-shaped aluminum frames for an automated system. The frames required tight tolerances and smooth edges for seamless integration.

Our Solution:

- Utilized advanced bend fabrication techniques for precise angles.

- Delivered 500 units with consistent quality and a polished anodized finish.

Results:

The client improved system efficiency and assembly time with high-quality, precision-formed frames.

Client Feedback:

The client praised the part’s exceptional quality and early delivery, enabling them to successfully integrate it into their robotics system and launch on time.

Impact:

This project reinforced Batnon’s reputation as a trusted CNC milling partner for high-precision, time-sensitive projects, particularly in the robotics and automation industries.

FAQs

1. What is the maximum thickness your metal bending machines can handle?

Our machines can bend metals up to 10mm thick, depending on the material type.

2. Can you handle custom designs for bending projects?

Yes, we specialize in custom bent sheet metal and tube fabrication, ensuring tailored solutions for unique projects.

3. What industries benefit from your metal bending services?

We serve industries including automotive, aerospace, medical devices, industrial equipment, and more.

4. What materials can you bend?

We work with a wide range of materials, including steel, aluminum, brass, and specialty alloys.

5. How precise are your metal bending capabilities?

We achieve tolerances as tight as ±0.25°, ensuring accuracy for even the most critical components.

6. What finishing options do you offer for bent metal parts?

We provide surface treatments such as plating, powder coating, anodizing, and polishing for enhanced functionality and aesthetics.

Ready to elevate your project

with our precision CNC machining services?