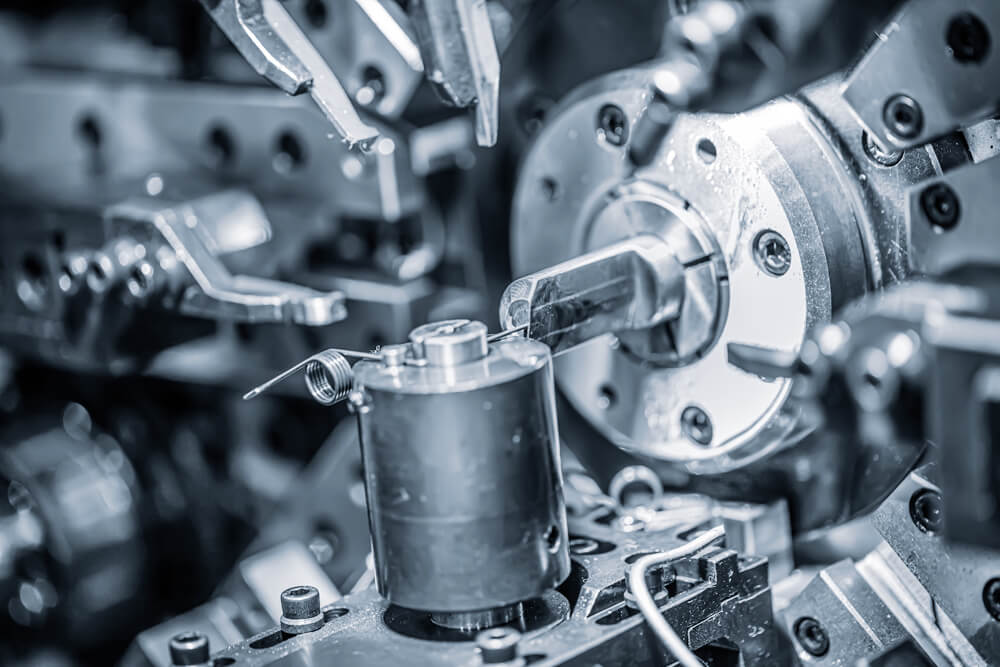

Precision CNC Machining Services: 3/4/5 Axis Capabilities

High-precision, multi-axis machining for complex and custom parts to meet your exact specifications.

Our CNC Machining Manufacture

At Batnon, we leverage advanced 3/4/5-axis CNC machining technology to manufacture high-precision components for industries requiring complex geometries and tight tolerances.

CNC Machining Capabilities at Batnon

1. Multi-Axis Machining Expertise

- 3-Axis Machining: Ideal for simple geometries and flat surfaces, offering cost-effective solutions.

- 4-Axis Machining: Enables machining on multiple sides of a part with precision and efficiency.

- 5-Axis Machining: Handles intricate designs and complex geometries with simultaneous movement on all axes, ensuring unmatched accuracy.

2. Material Versatility

We excel in machining a broad range of materials to suit diverse industrial needs:

- Metals: Aluminum, stainless steel, titanium, brass, copper, and more.

- Plastics: ABS, POM, Nylon, PEEK, and other engineering-grade materials.

3. Precision & Tolerances

- Achieving tolerances as tight as ±0.005mm, ensuring your parts meet exact specifications.

- Perfect for applications requiring critical precision, such as aerospace, medical devices, and electronics.

4. Advanced Technology

Our facility is equipped with cutting-edge CNC machines capable of handling:

- Complex 3D contours.

- Intricate internal cavities.

- Fine details like threads, slots, and grooves.

5. Scalability

- Prototyping: Rapid production of small batches to test and refine your designs.

- Mass Production: Consistent quality and efficiency for high-volume orders.

Advantages of Choosing Batnon for CNC Machining

- Precision & Accuracy: Tight tolerances down to ±0.005mm.

- Multi-Axis Expertise: Advanced 3/4/5-axis machines for complex geometries.

- High Production Efficiency: Faster turnaround with high repeatability.

- Material Flexibility: Ability to process metals, plastics, and specialty materials.

- Quality Assurance: ISO standards, inspection reports, and rigorous testing.

- Competitive Pricing: Cost-effective production without compromising quality.

Applications of CNC Milling

Examples of Parts:

- Enclosures and housings

- Engine components

- Brackets and supports

- Precision gears and shafts

- Custom tooling

Customization Options:

- Milling of features like grooves, channels, slots, or intricate patterns for aesthetic or functional purposes.

Advanced Technology:

- Equipped with state-of-the-art milling machines for high-precision results.

Customization:

- Flexibility to produce one-off prototypes or mass production runs.

Efficiency:

- Faster production with automated multi-axis milling machines.

Quality Assurance:

- ISO-certified processes with rigorous quality checks at every stage.

Surface Finishes:

- Ability to achieve smooth surfaces, deburring, and custom finishes for aesthetics or functionality.

Industries

- Automobile

Producing high-precision parts like engine components, transmission systems, and custom housings to improve vehicle performance and reliability.

- Automation

Crafting intricate components for automation systems, enabling seamless integration and optimized functionality in manufacturing lines.

- Medical

Manufacturing surgical tools, implants, and device components with stringent tolerances, ensuring safety and compliance with medical standards.

- Energy

Delivering robust parts for renewable energy systems, such as wind turbine components, and high-efficiency fittings for energy distribution.

- Robotics

Creating precision-machined parts for robotic arms, joints, and frames, ensuring high performance in dynamic and demanding environments.

- Electrical

Producing custom enclosures, connectors, and components for electrical systems, enhancing safety and conductivity.

- Aerospace

Delivering precision-engineered components with tight tolerances for critical applications like turbine parts, brackets, and structural elements in aircraft.

- Consumers

Crafting customized, high-quality parts for consumer goods, focusing on aesthetic appeal and durability.

- Food and Beverage

Producing sanitary and corrosion-resistant components for food processing equipment, meeting strict hygiene standards.

- Electronics

Manufacturing intricate parts like PCB enclosures, heat sinks, and connectors with high precision for compact and efficient electronic devices.

- Printing

Supplying durable and precision-machined components for printing presses, ensuring reliability and long-lasting performance.

- Machinery and Equipment

Creating heavy-duty parts like gears, shafts, and fixtures for industrial machinery, ensuring durability and optimal functionality.

- Aircraft

Specializing in precision machining for critical structural and mechanical components, ensuring safety and performance in aviation applications.

Materials

Metals:

Aluminum (6061, 7075, etc.) – Lightweight, corrosion-resistant, and versatile.

Stainless Steel (304, 316, 410, etc.) – Durable, strong, and corrosion-resistant.

Tool Steel – Ideal for high-strength tools, molds, and dies.

Spring Steel – Excellent elasticity and fatigue resistance.

Carbon Steel – High strength and excellent machinability.

Titanium – High strength-to-weight ratio, ideal for aerospace and medical.

Brass – Good electrical conductivity and corrosion resistance.

Copper – Excellent thermal and electrical conductivity.

Magnesium – Extremely lightweight and high machinability for automotive and aerospace applications.

Tungsten – Extremely dense, hard, and heat-resistant for specialized applications.

Invar – Exceptional dimensional stability with minimal thermal expansion, ideal for precision instruments and aerospace applications.

Kovar – Excellent thermal expansion compatibility with glass and ceramics, perfect for hermetic seals in electronic and optical components.

Plastics:

Acrylic

Delrin

Garolite G-10

HDPE

РЕЕК

Polycarbonate

Polypropylene

PPS

PTFE

PVC

Torlon UHMW

Ultem

Other Specialty Materials:

NBR Nitrile, silicone, rubber, Engineering Plastics.

Material Recommendations:

Aerospace & Medical: Use Titanium, Stainless Steel, or PEEK for strength and precision.

Automotive & Industrial: Aluminum, Carbon Steel for balance of cost and performance.

Electronics: Copper and Brass for electrical conductivity.

Prototyping: ABS, Nylon, or Aluminum for cost-efficiency and fast production.

Tolerances

- Standard Tolerance: ± 0.01 mm (typical)

- High Precision: Down to ±0.000039″ / ±0.001mm, achievable based on customer requirements.

Tolerances Matter

“In industries like aerospace, medical devices, and automotive, even minor deviations in tolerances can lead to functional failures or poor part fit. At Batnon, we ensure every part meets exact specifications through our advanced multi-axis CNC machining technology.”

Surface Finishes

- As-Machined: Smooth, standard finish directly from the CNC process.

- Polished: Reflective, glossy surface.

- Anodizing: Enhances corrosion resistance and aesthetics (available in multiple colors).

- Powder Coating: Durable finish for wear resistance.

- Sandblasting: Uniform matte surface.

- Plating: Nickel, zinc, or chrome plating for functional or decorative purposes

- Galvanizing:Zinc coating applied to steel or iron parts for enhanced corrosion resistance and durability, ideal for outdoor or industrial applications.

- Electrophoresis: A uniform, electrically-applied coating that enhances corrosion resistance and provides a smooth, durable surface finish, suitable for decorative or functional purposes.

- Tumbling: A finishing process that smooths and polishes parts by gently rotating them with abrasive media, ideal for removing sharp edges and achieving a uniform matte or polished finish.

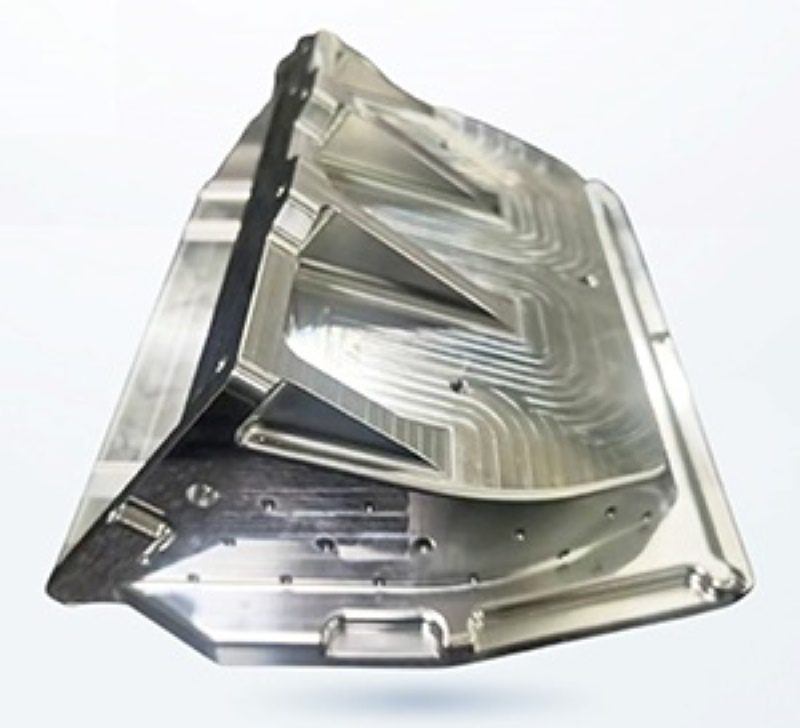

Case Study

Project Requirement:

An automotive client approached Batnon for the production of a custom aluminum housing used in a high-performance electric vehicle system. The project required the part to meet a strict tolerance of ±0.005mm to ensure seamless assembly with other critical components. The housing design included intricate internal features and sharp edges, making it a perfect fit for our custom CNC milling capabilities.

Results:

- Precision Achieved: Maintained a dimensional accuracy of ±0.005mm across all critical points, ensuring perfect alignment with other components during assembly.

- Lightweight and Durable: The frame weighed 15% less than traditional designs while maintaining superior strength.

- On-Time Delivery: Completed production within 12 days, ahead of the client’s 15-day deadline.

Client Feedback:

The client praised the part’s exceptional quality and early delivery, enabling them to successfully integrate it into their robotics system and launch on time.

Impact:

This project reinforced Batnon’s reputation as a trusted CNC milling partner for high-precision, time-sensitive projects, particularly in the robotics and automation industries.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Need a specific material or precision tolerance?

Our experts will tailor solutions to meet your requirements

FAQs

1. What types of materials can Batnon machine with CNC technology?

We specialize in precision machining of a wide range of materials, including aluminum, stainless steel, titanium, brass, and engineering plastics like PEEK and ABS. Our expertise in precision metal products ensures we can meet the needs of various industries requiring tight tolerances and superior finishes.

2. How do you ensure the quality of CNC-machined parts?

Batnon uses advanced inspection tools like 3D Coordinate Measuring Machines (CMMs) to verify dimensions and tolerances. Each project undergoes rigorous testing to ensure the highest level of precision engineering and consistent quality across all machining parts.

3. What industries does Batnon support with CNC machining services?

We provide cnc services for a diverse range of industries, including aerospace, automotive, medical devices, electronics, robotics, and industrial equipment. Our flexibility as a leading machining manufacturer allows us to cater to both large-scale and niche production needs.

4. Can you produce custom parts for specialized applications?

Yes, we excel in custom CNC manufacturing, crafting intricate parts tailored to your exact specifications. Whether you need components for robotics, automation, or medical devices, our team ensures unparalleled precision manufacturing.

5. What is the maximum size of parts you can machine?

Our CNC machines handle parts up to 1000mm x 500mm x 400mm, making us capable of producing both small, intricate components and large machining parts with high accuracy.

6. How quickly can Batnon deliver CNC-machined parts?

Lead times vary depending on the complexity and quantity of your order. Prototypes can be delivered within 7–10 days, while bulk production typically takes 2–4 weeks. Our efficient machining services ensure timely delivery without compromising on quality.

7. How does Batnon balance quality and CNC machining cost?

We utilize advanced technologies and optimized workflows to provide competitive cnc machining costs while maintaining exceptional quality. Our approach ensures that clients receive value-driven metal machining solutions tailored to their needs.

8. Do you offer design assistance for CNC machining projects?

Yes, we collaborate closely with clients during the design phase. Our team of precision engineering experts provides recommendations to enhance manufacturability, improve part performance, and reduce production costs.

9. Can you handle high-volume production runs?

Absolutely. As a trusted machining vendor, we are equipped for both low-volume prototyping and high-volume production, ensuring scalability and consistency in every order.

10. What makes Batnon different from other machining vendors?

Our commitment to precision, advanced cnc manufacturing capabilities, and expertise in crafting precision metal products set us apart. We pride ourselves on delivering tailored solutions that meet even the most demanding industry requirements.

Ready to elevate your project

with our precision CNC machining services?