Our Die Casting

At Batnon, we specialize in manufacturing die casting components that combine precision, strength, and efficiency. With advanced technology and a dedicated team, we deliver custom die cast products that meet the highest industry standards, whether for prototyping or large-scale production.

Overview on Die Casting at Batnon

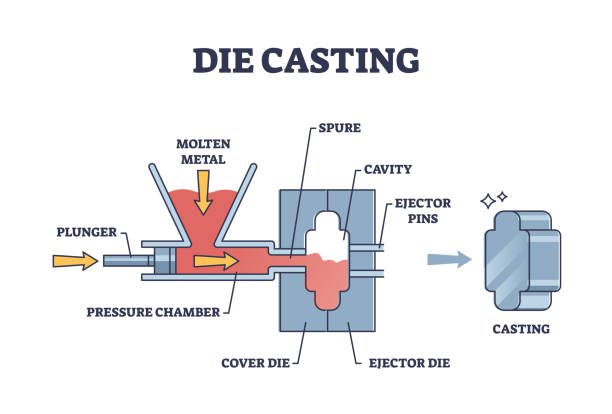

Define die casting: Die casting is a high-pressure manufacturing process where molten metal is injected into reusable steel molds, known as dies, to create complex and durable components. At Batnon, our expertise in the die casting process ensures high-quality results tailored to various applications and industries.

Our Die Casting Capabilities

Key Capabilities of Batnon’s Die Casting Services

- Types of Die Casting: Expertise in both hot chamber die casting (for low-melting metals like zinc) and cold chamber die casting (for high-melting metals like aluminum).

- Part Size: Accommodates small to medium-sized components with intricate geometries.

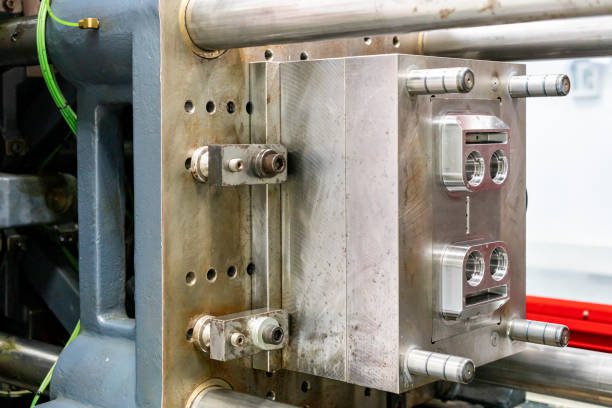

- Tooling Expertise: Precision-engineered die casting dies to ensure optimal performance and repeatability.

- Production Scalability: Supports both small-batch and high-volume manufacturing needs.

Special Features

- Thin wall casting for lightweight applications.

- Secondary processes, such as trimming, polishing, and plating, for a finished product.

Why Choose Die Casting with Batnon?

- High Efficiency: Rapid production cycles for high-volume orders.

- Superior Strength: Die-cast parts combine lightness and strength, ideal for demanding applications.

- Cost-Effectiveness: Reduced material waste and minimal machining required.

- Excellent Surface Finishes: Achieve smooth, uniform surfaces suitable for plating, painting, or anodizing.

- Material Versatility: Compatibility with a wide range of die cast materials, including aluminum, zinc, and magnesium.

Applications of CNC Milling

Industries Served

Batnon’s die casting manufacturing serves a broad range of industries:

- Automobile: Lightweight engine components, transmission housings, and brackets.

- Automation: Custom die-cast parts for automated systems and machinery.

- Medical: Durable housings and components for medical devices.

- Energy: Die-cast heat sinks and structural components for renewable energy systems.

- Robotics: Precision parts like joints, frames, and motor housings for robotic systems.

- Electrical: Compact, high-strength enclosures and connectors.

- Aerospace: Lightweight yet durable parts for critical aerospace applications.

- Consumers: Decorative and functional components for high-end consumer products.

- Food and Beverage: Corrosion-resistant parts for food processing equipment.

- Electronics: Die-cast housings, brackets, and heat sinks.

- Printing: Durable components for printing presses and machinery.

- Machinery and Equipment: Custom-engineered die-cast parts for industrial applications.

- Aircraft: Structural components and housings for aircraft systems.

Materials

Die Cast Materials We Use

- Aluminum: Lightweight, corrosion-resistant, and ideal for structural applications.

- Zinc: Excellent for intricate details and high durability.

- Magnesium: Lightweight and strong, perfect for aerospace and automotive applications.

- Special Alloys: Designed for specific applications requiring enhanced properties.

Material Recommendations

Batnon works with a variety of die cast materials, each tailored to specific application needs. Below are our recommendations based on common requirements:

Aluminum Alloys: Lightweight, corrosion-resistant, and thermally conductive. Ideal for automotive, aerospace, and electronic components.

Example: Engine housings, brackets, and heat sinks.Zinc Alloys: Known for their excellent dimensional stability and ability to create intricate details. Perfect for small, complex parts.

Example: Connectors, housings, and fasteners.Magnesium Alloys: Extremely lightweight with high strength, suitable for applications demanding weight reduction without compromising performance.

Example: Aircraft and automotive components.Specialty Alloys: Custom blends designed to meet the specific needs of industries like medical, robotics, or energy systems.

Example: High-heat or corrosion-resistant components for specialized equipment.

Tolerances

- Standard Tolerance: ± 0.01 mm (typical)

- High Precision: Down to ±0.000039″ / ±0.001mm, achievable based on customer requirements.

Tolerances Matter

“In industries like aerospace, medical devices, and automotive, even minor deviations in tolerances can lead to functional failures or poor part fit. At Batnon, we ensure every part meets exact specifications through our advanced multi-axis CNC machining technology.”

Surface Finishes

To enhance the functionality and appearance of die cast products, Batnon offers a range of professional surface treatment options:

Plating:

- Nickel, Zinc, or Chrome Plating for added corrosion resistance, durability, or decorative purposes.

Powder Coating:

- Durable, uniform coating that enhances the appearance and provides excellent resistance to wear and corrosion.

Polishing:

- Achieves a smooth, shiny finish ideal for decorative or functional applications.

Anodizing:

- Provides a protective oxide layer for aluminum parts, improving corrosion resistance and enabling various color options.

Tumbling:

- A cost-effective method to remove sharp edges, burrs, and achieve a uniform matte finish.

Electrophoresis:

- A uniform coating applied through electrical deposition, ideal for parts requiring enhanced corrosion resistance.

Galvanizing:

- Zinc coating for steel or iron parts to improve corrosion resistance in industrial or outdoor applications.

Navigating the complexities of die casting dies and material selection can be challenging. At Batnon, our experts are here to help you find the right solution for your project, ensuring optimal results and cost efficiency.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Case Study

Project Requirement:

An automotive client needed a lightweight yet strong die cast metal bracket for an electric vehicle. The part required complex geometries and a smooth surface finish for functional and aesthetic purposes

Our Solution:

- Designed and optimized die casting dies for high precision.

- Utilized aluminum alloy for its lightweight and corrosion-resistant properties.

- Produced 10,000 units with consistent quality and delivered ahead of schedule.

Results:

- The client reduced vehicle weight, improving energy efficiency without compromising on strength or durability.

Client Feedback:

The client praised the part’s exceptional quality and early delivery, enabling them to successfully integrate it into their robotics system and launch on time.

Impact:

This project reinforced Batnon’s reputation as a trusted CNC milling partner for high-precision, time-sensitive projects, particularly in the robotics and automation industries.

FAQs

1. What types of die casting do you offer?

We provide hot chamber die casting for materials like zinc and magnesium and cold chamber methods for aluminum and specialty alloys.

2. What are the benefits of die casting compared to other methods?

Die casting offers high precision, fast production, excellent surface finishes, and minimal material waste, making it ideal for high-volume manufacturing.

3. Can you produce large quantities of die-cast products?

Yes, our processes are optimized for high-volume production while maintaining consistent quality across all units.

4. What materials are suitable for die casting?

We work with die cast materials like aluminum, zinc, magnesium, and custom alloys to meet specific application needs.

5. How precise are the components produced through die casting?

We can achieve tolerances as tight as ±0.02mm, ensuring excellent dimensional accuracy for every part.

6. What industries do you serve with die casting services?

Our die casting manufacturing supports industries such as automotive, aerospace, electronics, medical devices, and more.

7. Do you offer additional finishing options for die-cast parts?

Yes, we provide various surface treatments, including polishing, plating, and powder coating, to enhance functionality and appearance.

Ready to elevate your project

with our precision CNC machining services?