Service - Integrated Processing

About Integrated Processing

At Batnon, our production theory revolves around the concept of “Integrated Processing.” This innovative approach combines various manufacturing technologies, methods, machinery, software, and skilled labor to deliver products efficiently, cost-effectively, and with unparalleled speed. This page explains the details of our Integrated Processing model and why we excel at it.

What is Integrated Processing?

Integrated Processing is the systematic merging of diverse manufacturing technologies into a unified workflow. It includes:

Technology Integration: Combining CNC machining, plastic molding, die casting, and other processes into a single production ecosystem.

Efficient Resource Allocation: Utilizing advanced machinery and software for optimal resource utilization.

Labor Coordination: Ensuring seamless collaboration between skilled technicians and engineers.

Sustainable Practices: Reducing waste through precise planning and execution.

Why Choose Batnon for Integrated Processin

1. Advanced Machinery & Equipment

We invest in cutting-edge machinery to ensure precision and scalability. Our machines are capable of multi-functional operations, reducing the need for multiple setups and transfers.

2. Experienced Team

Our team comprises seasoned engineers, designers, and operators who are experts in their fields. This expertise enables us to handle complex projects with ease.

3. Software Integration

We employ advanced software to monitor, plan, and optimize production workflows. Real-time data tracking ensures efficiency and quality.

4. Sustainable Practices

By minimizing material waste and energy consumption, we align our operations with environmentally responsible practices.

5. End-to-End Solutions

From prototyping to final delivery, we offer a one-stop solution that saves time and reduces costs for our clients.

The Key Components of Integrated Processing

1. Manufacturing Technologies

We integrate processes like:

CNC machining for precise parts

Injection molding for durable components

Die casting for complex shapes

Surface treatments like anodizing and plating

2. Seamless Workflow

Process Synchronization: Ensures every stage flows seamlessly into the next.

Real-Time Monitoring: Identifies bottlenecks and optimizes production.

3. Customization Capability

We tailor our processes to meet the specific needs of clients, offering custom designs and scalable production.

4. Quality Assurance

Our integrated approach includes rigorous quality checks at each stage, ensuring high standards of performance and reliability.

Advantages of Integrated Processing

1. Cost Efficiency

Combining processes reduces redundancy and lowers production costs.

2. Time Savings

Streamlined workflows enable faster turnaround times.

3. Enhanced Flexibility

Quick adaptation to changes in project requirements.

4. Improved Product Quality

Tightly controlled processes result in consistently high-quality outputs.

5. Reduced Environmental Impact

Integrated planning minimizes waste and conserves resources.

Examples of Integrated Processing in Action

Case Study 1: Multi-Technology Product Development

We combined CNC machining, plastic molding, and assembly for a client’s custom project, cutting production time by 40%.

Case Study 2: Rapid Prototyping to Mass Production

Using our integrated process, we transitioned a prototype into mass production within a month, ensuring quality and cost-effectiveness.

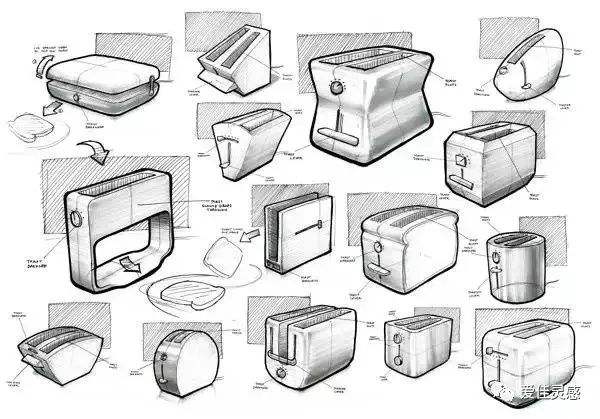

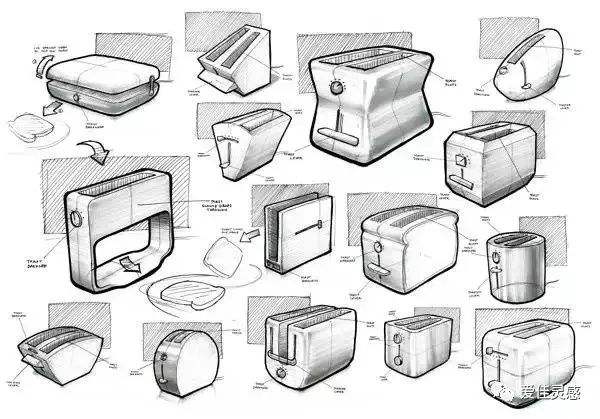

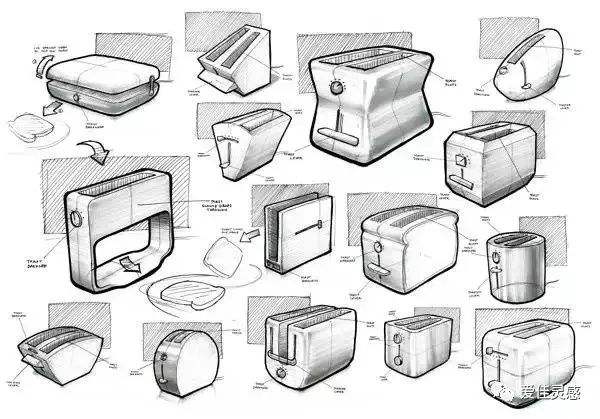

2. New Product Development

Transforming ideas into market-ready products is one of our specialties. Our product development services are designed to turn concepts into tangible outcomes.

What We Offer:

Prototyping: Rapid prototype development to validate designs and functionality.

Material Sourcing: Access to a wide network of reliable suppliers for diverse material needs.

Iterative Refinement: Collaboration to improve designs based on performance, usability, and cost.

Scalability: Development processes that align with your production scale requirements.

Why We Excel:

Extensive experience across multiple industries.

A dedicated team of engineers and designers focused on innovation.

State-of-the-art tools and technologies for precision development.

How We Continue to Innovate

R&D Investments: Continuously upgrading our machinery and techniques.

Training Programs: Keeping our workforce at the forefront of industry developments.

Client Collaboration: Working closely with clients to align our processes with their goals.

Ready to experience the benefits of Integrated Processing? Reach out to us to discuss your project and learn how we can bring your ideas to life efficiently and cost-effectively.