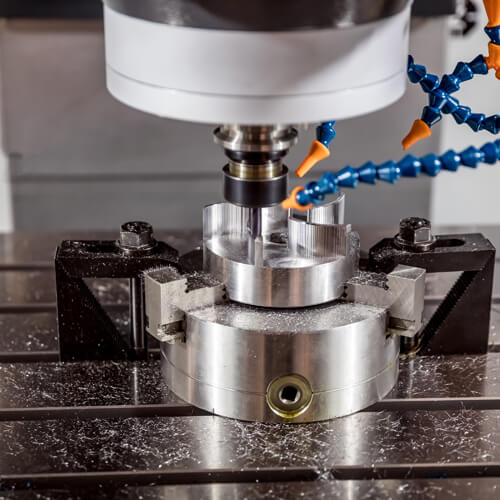

CNC machining is realized by CNC machine tools. Therefore, the stability of CNC machine tools directly affects the effect of CNC machining. What factors affect the stability of CNC machining?

1. Voltage stability

If the voltage is unstable, the actions of the moving parts of the machining machine will also appear some unstable states with the fluctuation of the voltage, such as the fast and slow phenomenon of tool movement and rotating speed, which will affect the stability of CNC machining.

2. Lubrication

Lubricating oil is needed between the contact surfaces of some parts in the machining machine to reduce the friction. If the lubricating oil is insufficient, the parts in the machine are easy to wear during operation, so it is easy to cause deviation in the machining accuracy of the workpiece in CNC machining, and even some defective products.

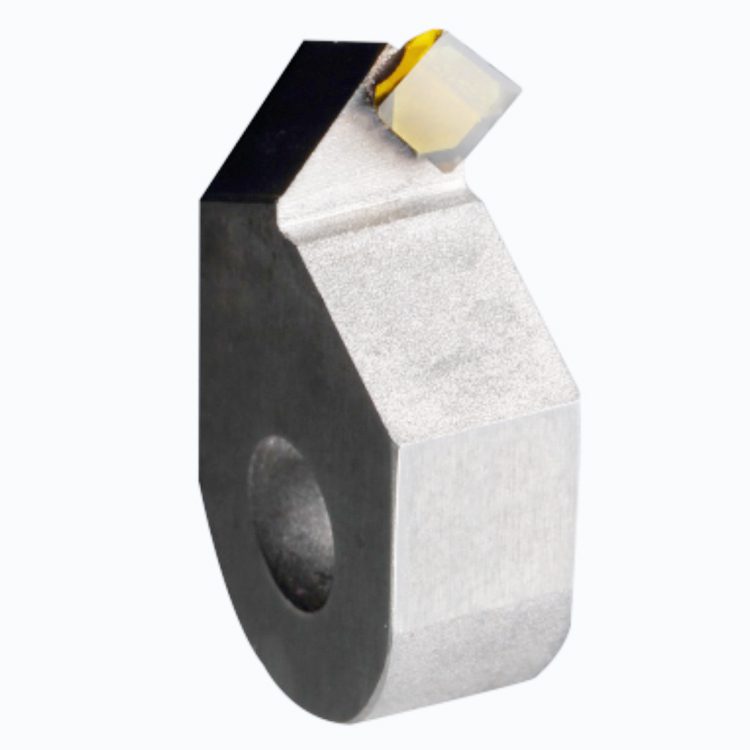

3. Mechanical components and parts

The parts and components used in general processing machinery should be replaced at intervals due to wear. However, if the quality of the parts used is not good, it is easy to cause excessive wear, and it is often easy to cause instability or even failure of CNC processing.

4. Heat dissipation problem

If the machine works for a long time without timely heat dissipation, it is easy to cause overheating inside the machine, or even shutdown, which affects the stability of processing.