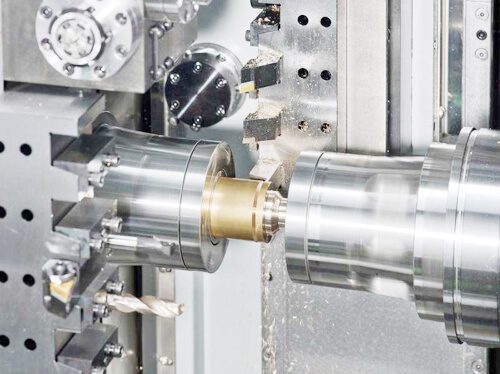

In the use of CNC machine tools, its processors need to master some detailed knowledge. The following is about the preparation of CNC machine tools before machining.

What are the preparation steps before CNC machine tool processing

When starting or stopping the CNC machine tool of the CNC machine tool equipment (whether horizontal or vertical), first make the CNC machine tool reference zero and make the CNC machine tool operated later in the referenced position.

1. CNC machine tool clamping workpiece

Before clamping the workpiece, the operator of the CNC machine tool needs to clean each surface that can not be stained with iron filings, dust and oil. The operator also needs to use a file or oilstone to remove the burrs on the workpiece surface. The iron block for clamping must be polished with a grinder to make all surfaces smooth and flat. Iron pads are generally placed at the four corners of the workpiece. For parts with too large span, contour iron pads must be placed in the middle; Check whether the length, width and height of the workpiece are qualified with a ruler according to the dimensions of the drawing.

When the CNC machine tool clamps the workpiece, the clamping shall be carried out according to the programming operation instructions, and the opening is required to avoid the cutter head from contacting the fixture. When the workpiece is placed on the iron pad, according to the requirements of the workpiece reference drawing, the CCNC machine tool operator shall test whether its perpendicularity meets the ground workpiece. After the workpiece pulling table is completed, the nut must be tightened to prevent loose clamping and dislocation of the workpiece in displacement processing. The operator needs to pull the CNC machine tool workbench again to ensure that the clamping error does not exceed the specified value.

2. CNC machine tool-workpiece collision times

The parts clamped by the CNC machine tool can use the collision head to set the reference zero position of the touch number, and the collision head can use photoelectric and mechanical methods. There are two methods: the number of intermediate collisions and the number of unilateral collisions.

3. Tool preparation of CNC machine tools

The programmer selects the parts to be processed, generates the tool path through the cam software UG programming, carries out the interference inspection through the UG simulation module, processes after the interference inspection, and generates a safe and stable CNC code. Then they transfer it to the workshop and then to the CNC machine tool.

Prepare all tools according to the programming instructions, replace the processing tools, and let the tools contact the height gauge placed on the datum plane. When the red light of the height gauge is on, set the relative coordinate value of this point to zero Move the tool to the safe position, manually move the tool down 50mm, and then set the relative coordinate value of this point to zero, that is, the zero position of Z axis.

Record the mechanical coordinate Z value of this point in one of the CCNC machine tools g54 ~ G59. This completes the zeroing of the X, y and Z axes of the workpiece. Carefully check the correctness of the data again. In addition, the operator of the CNC machine tool also needs to check the correctness of the zero point, move the x-axis and y-axis to the lateral position of the workpiece, and visually check whether the zero point is correct according to the size of the workpiece. Copy the program file to the computer according to the file path of the programming operation instruction.

This article mainly introduces the preparation steps before CNC machine tool processing. Browsing this article, you can understand that when CNC machine tool equipment (whether horizontal or vertical) CNC machine tool starts or stops, first make the benchmark of CNC machine tool zero, so that the CNC machine tool operated in the future is in the benchmark position.